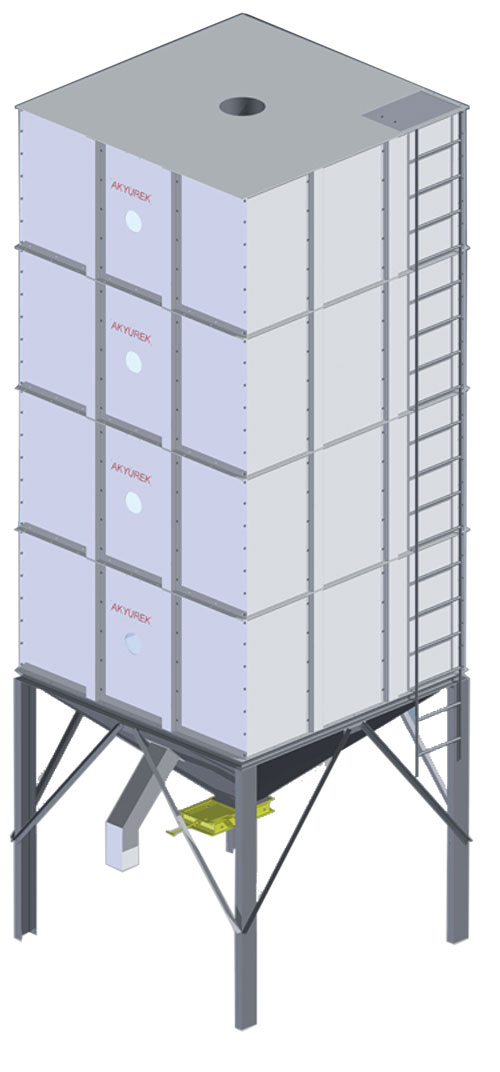

INDOOR SQUARE SILOS

Indoor Square Silos are designed and manufactured for food processing and or industrial plants product storage purposes. Akyurek Technology designs, manufactures and supplies with helper equipments for Square silos usage purpose i.e product feeding elevators, roduct drop down slower, capacity sensors, mechanical outlet valves, pneumatic valve outlets, capacitive measurement outles, second outlet (for big bag filling i.e) magnetic feeders, cooler and heaters.

Wall Sheets

for the bins are manufactured from suitable material for customer demand hot galvanized steel sheets, Stailess Steel, Owen Coated Painted ST 37 Carbon Steel Sheets which are Laser Cut for maximum rigidity obtained. Accurate prcesses on the production line ensures a tight fit and easy erection. Depending on wall element length and to what total height bins will have to be, different sheet thicknesses have to be selected.

Sensor

Capacity or level sensors can be designed and supplied as an option with silos. Capacity or level sensors can be designed and supplied as an option with silos.

Inspection Window

Acrylic window allows visual inpection of the level of stored product.

The Rods

By using tie rods, larger bins can be supported. This is done by installing steel pin supports cross to walls. They are delivered in corresponding lengths to the walls sheets.

Corner Post

Corner posts are available in 2 designs according to the illustrations. Type 1- where four walls are jointed together with Nut Bolt and Washer Joints Type 2-Square profile steel bars welded where four walls are jointed together. where four walls are jointed together. The posts are available as standard painted or hot dipped galvanized. Apart from standard posts above, there are a number of posts for special purposes, for instance, when hoppers are fitted.

Nut, Bolt & Washer

Bolts, washer and Nuts are used for assembling the wall parto join corner posts and wall sheets, flanged bolts M8 and nuts galvanized, are used No washers are neccessary because of the flanged nuts. This gives easier erection.

Loadcells

Weighing of stored goods in silo and using this data.

Hooper Vibrator

Hopper Vibrators developed to facilitate flow from bins and hoppers on all types of materials, including large aggregate and sand, fine powders, flakes, pills, bottle caps, jars and just about any material that tends to stick or clog inside a silo.

Outlet Valves

Silos are supplied with manual operated outlet valves in its standard for product/seed discharge control system. As an option manual operated ball bearing equip outlet valves or auto controlled pneumatic outlet valves are available upon request.

Leg Stands

If the silo is to be fitted with outlet clearance, it is required that the lower section is elevated to the level of the outlet chute. Legs to fit under the corner-posts are available in various lengths in order to suit the outlet clearance. They are delivered either painted or galvanized.

Second Outlet

Easy discharge of excess roduct from the silo in to i.e a big bag, elevator hopper, conveyor belt.

Ultrasonic Sensor

Ultrasonic sensors measure the distance or presence of target objects by sending a pulsed ultrasound wave at the object and then measuring the time for the sound echo to return. Knowing the speed of sound, the sensor can determine the distance of the object.

Lid

Silo lid keeps stored product safe from external contanmination possibilities. Safe and Healthy Storing at maximum.

Lid Opener

Provides entrence to operator inside of silo for cleaning, service and maintanance.

Ladder Out-In

Provides acess inside of silo for cleaning, service and maintanance.

Easy Down

In order to avoid damage on product whilst handling necessary equipments are designed and supplied.