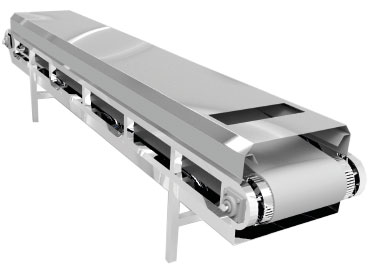

Conveyor Belt

Akyurek Technology manufactures variety of belt conveyor systems whether be indoor or outdoor, bulk, box or bagged commodities

Belt Conveyors have a wide variety of functional applications from conveying bulk seed, fruit, boxes, wood, sand, coal est. from point A to B, vertical or inclined, distances from 0,50 to 60 meters or more, capacities 100kg to 50 tons / hour or more, single discharge or multiple discharge points.

Function

This machine is used to bad bagged or bulk products onto the trucks or to unload the same. Owing to its light and compact structure it can be easily carried. Height of the machine is adjustable and this can be made either automatically r manually. Stanndart dimesinons has state in detailed list.

Work Principle

An infinitive belt which turns on two drums (tambours) carries the bags from the lower point to uppet point. The surface of the conveyor belt is rough and knobby so that it prevents the bags from sliping back-down. The height of the apparatus is adjusted manually. Alsı bya conical roll system hollows are obtained and so the correct result is reached in carrying the bags up.

Optic Counter Loading Belt

Helps accurate counting of the loaded product. An easliy and simply installable ancillary unit.

Flat Type Box Conveying Belt

Carrier rollers are manufactured for conveying boxes. Edge barriers can be attached to ban box falling during transport.

V Model Bag Conveyor

Conveyor is manufactured in conic shape to prevent bag falling during transport. Also, V Models mounted onto the belt prevent slipping back of bags. Bulk products are transportable with this.

Container Type Loading Belt

Front side of belt shall be made long so that it goes through the container. Container loading is a system smootheing conveyance.

Height Adjustable System with Mechanical Armrest

Belt height is adjusted by operator with the mechanical armrest. Being strengthened with the auxiliary reel, the system provides smoothness of unloading and lifting.

Height Adjustable Automatic Motor System

Belt height is adjusted by the reducing motor. The advantage of this system is its capability to smoothly adjust height in long model belts without need to manpower. Furthermore, the system provides advantage of security of operation.