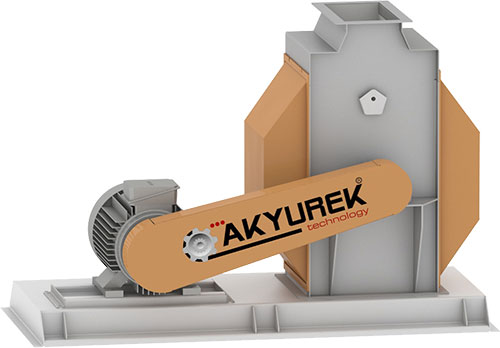

HAMMER MILL AKYUREK HMAK

Akyurek Technology is a leading manufacturer of grain food processing equipment.

Akyurek hammer mills grind various products from grain and hulling mills, from breweries and also from feed mills and produce high quality fine grind for mash filtration. The Akyurek hammer mill HMAK functions as a fine grinding mill in food or feed plant production and as a course grinding mill in the formulated feed manufacturing, flour milling and biomass industries.

Efficient and powerful size reduction via Optimized design.

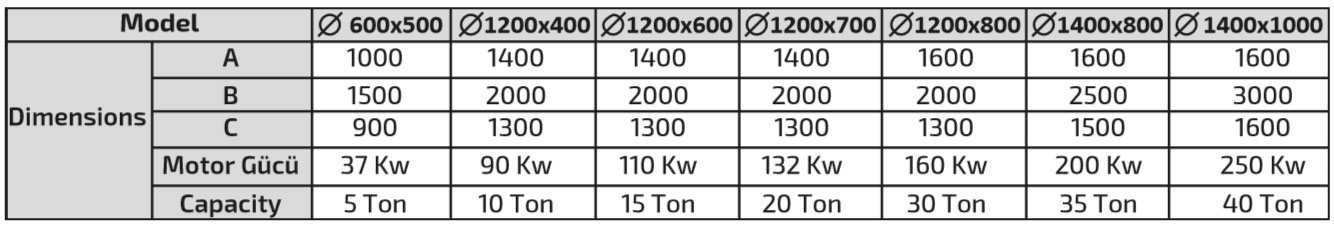

Maximum material contact for proper, efficient size reduction achieved by HMAK's optimal hammer design, placement and optimum hammer bar velocity. Optimal discharge of crushed particles achieved by sophisticated screen design thus reducing energy consumption. Top performances can be delivered by powerful motor with up to 250 kW

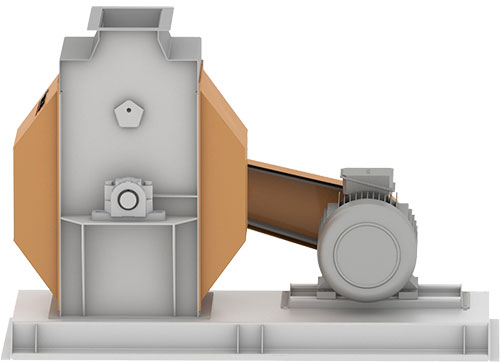

Save time with fast and easy screen and hammer changes.

Easy access to the screens via smart door design. No frames screens requires no tools when exchanging them. Fast and easy access to the hammers with the hammer bar locking mechanism.

Ability to produce a wide range of particle sizes

Material bulk density around 0.2 to 0.8 kg/dm3 with moisture up to 15% for fine grinding, the HMAK hammer mill equipped with fine screens for particle sizes ranging from 0.3 to 1.5 mm.

Material bulk density must be 0.2 to 0.8 kg/dm3, with moisture up to 15% for course grinding, the HMAK hammer mill equipped round-hole screens for particle sizes ranging from 1.5 to 8.0 mm.