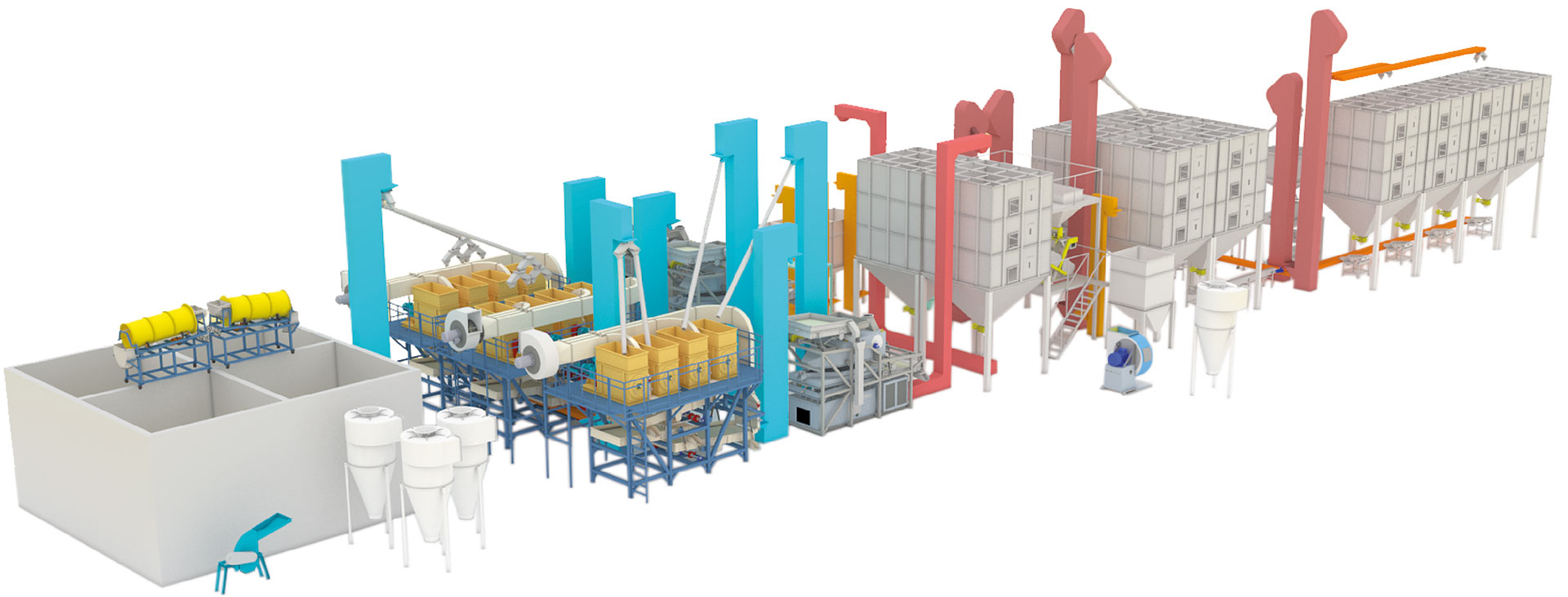

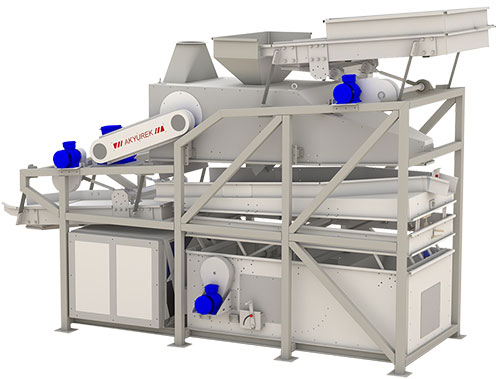

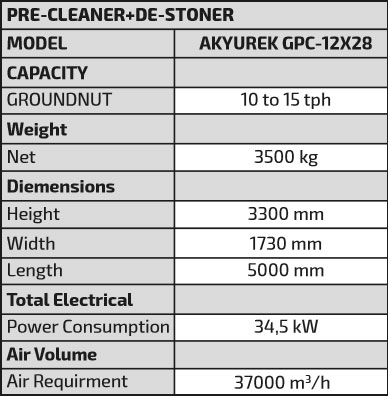

PRE-CLEANER + DE-STONER

Akyurek Technology ‘Pre-Cleaner+De-Stoner’ approves its self with its efficient and successful concept.

Separations of admixtures at first stage in cleaning process allows for increased efficiency. Performing foreign material separation early in the cleaning process allows for increased efficiency by downstream processing equipment. When receiving product at beginning of season, unload time is very important. Akyurek Technology ‘Pre-Cleaner+De-Stoner’ can work at high capacity volumes of product, while performing accurate and precise cleaning.

Pre-Cleaner+De-Stoner machine has got 3 Stages;

Stage 1- Screen Boat with 2 Levels of Screen for ‘Scalping’ & ‘Screening’ designated to separate ‘oversize admixtures’ like long sticks and large stones and ‘undersize admixtures’ like sand and fine dust separated by sand screen.

Stage 2-De-Stoner with efficient density separation of heavier admixtures like stones, rocks, glass or any other admixture heavier than Ground Peanut.

Stage 3- Screen Boat with Single Screening Level to separate loose Peanut Kernels that are already shelled from its husk during field to warehouse trip so loose kernels can be processed separately and safely.